Embrace the future of craniofacial surgery with the maxillofacial mesh plate, a breakthrough in orthopedic implant technology. These meticulously crafted devices are designed to meet the complex demands of modern facial and skull reconstructions, offering a new standard of precision and patient care.

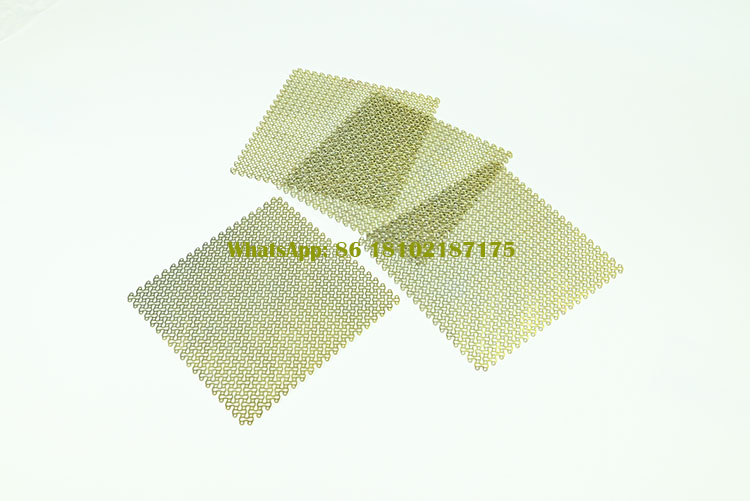

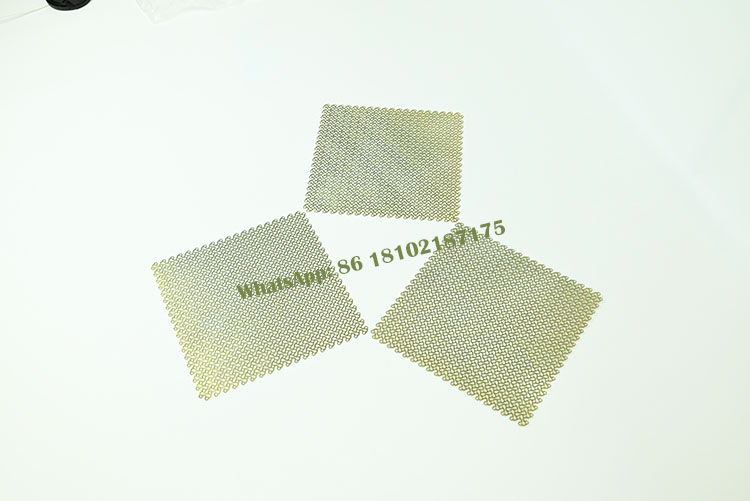

Titanium maxillofacial mesh plates are expertly fashioned, ensuring optimal fit and functionality for every patient. These plates are meticulously crafted from premium titanium, available in a wide range of sizes and customizable configurations to meet the specific needs of each surgical case. The 0.6mm thickness strikes the ideal balance between strength and flexibility, allowing the implant to blend seamlessly with the patient's individual anatomy.

| Product Name | Specification | Thickness |

| Maxillofacial Mesh Plate | 100*100mm | 0.6mm |

| 120*120mm | ||

| 120*150mm | ||

| 150*150mm | ||

| 200*200mm |

The maxillofacial mesh plates are widely applied in various aspects, for example, to mend fractures, perform osteotomies, as well as rectify misaligned fractures and non-unions. The extensive functionality of these implants renders them an extremely useful instrument in the treatment of craniofacial traumas and deformities.

The maxillofacial mesh plate is fashioned with an arched design that interfaces with each opening, obviating the distortion related to conventional meshes, and facilitating the facile bending and shaping to conform to the irregular contours of the skull. The one-of-a-kind rib reinforcement layout augments the mesh's plasticity and stiffness, furnishing a lightweight yet highly protective covering for the brain

The absence of iron atoms in the titanium mesh eliminates magnetization in magnetic fields, ensuring no interference with post-operative imaging such as X-rays, CT, and MRI scans. The maxillofacial mesh plate's stable chemical properties and excellent biocompatibility make it an ideal material for intracranial repair, with fibroblasts able to grow into the mesh holes post-surgery, integrating the titanium mesh with surrounding tissue.

The precise low-profile counter bore design of the accompanying screws allows for a close fit with the maxillofacial mesh plate, achieving an aesthetically pleasing and low-profile repair effect. The optical etching technology used in the manufacturing process ensures uniformity in the size and distance of the mesh holes, contributing to the overall performance and reducing the risk of skull re-fracture.

About Well Trust

Our factory was established in 2005, with a professional manufacturing team and lunging import and export experience. The orthopedic implant manufacturing facility is a state-of-the-art production center dedicated to the development and production of high-quality orthopedic implants.

We specialize in the manufacturing of a wide range of orthopedic implants, including screws, plates, and nails, catering to various surgical specialties such as trauma, spine, joint reconstruction, and sports medicine. Our implants are crafted from biocompatible materials such as titanium, stainless steel, and advanced polymers, offering optimal strength and compatibility with the human body.

With a customer-centric approach, we strive to build strong partnerships with healthcare providers, surgeons, and distributors worldwide. With a focus on quality, innovation, and sustainability, we are committed to being a trusted partner in the orthopedic industry.